Tool

Making

We ensure high precision and prime quality tool making – from standard tools to complex multi-component tools.

Tool Making as One of our Key Assets

We have a global tool shop setup with high-precision production expertise and state-of-the-art equipment. Ranging from standard to complex multi-component tools, we not only provide our own production but also design and deliver tools for various leading industries.

Our global customers appreciate our expertise and innovative strength in this sector. In Austria, complex tools including rapid tools for sampling processes are developed and produced.

In addition, numerous high-precision and high-end tools are produced in our 1,000 square meter tool shop in Hungary. The portfolio includes injection molds for the processing of thermoplastic materials and metal die casting tools.

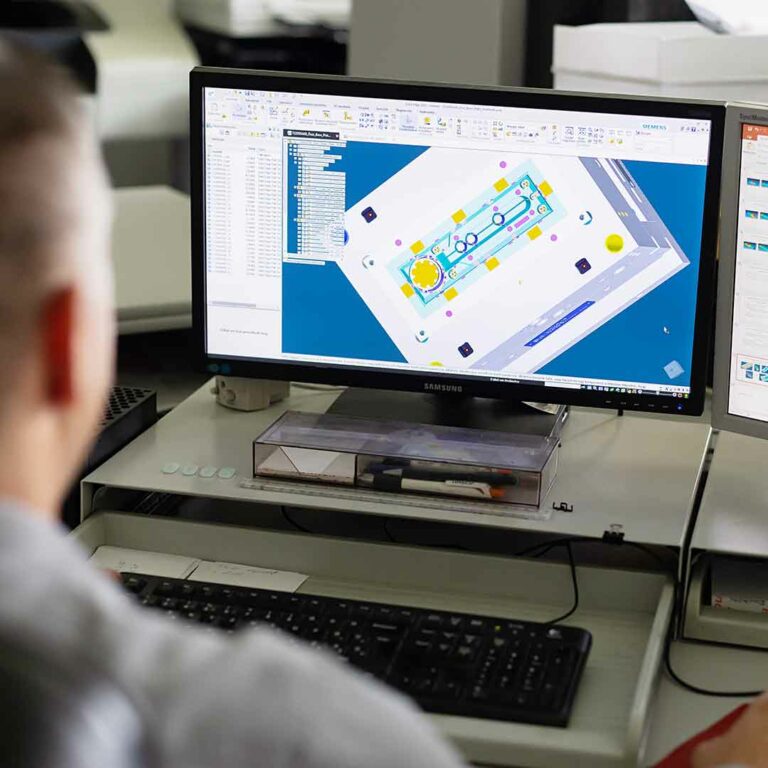

Providing ideal solutions in terms of technology, quality, and costs, the planning and conception of tools is supported by simulation software. Based on the design for our manufacturing principles, the reliable functionality and producibility of the tools are optimized and proven during initial sampling with the initial sample inspection report (ISIR). As soon as the proof of process capability has been provided, the qualification follows, all supported by a suitable risk management (FMEA tool).

“

“

Facts

Global tool shop setup for rapid tooling and serial manufacturing

Concept and construction supported by mold-flow simulation

Multi-cavity hot runner systems

Multi-component tools

Plastic/metal overmolding tools

Service portfolio

- Computer aided tool design 2D/3D and injection molding simulation

- Multi-cavity tools including hot runner system with valve gate

- Multi component tools (rotary table, index plate and turn-over tools)

- Precision tools

- Tools for optic parts, optical fiber parts etc. (PC, PMMA, …)

- In-mold decoration tools (IMD)

- Metal compound tools

- Metal die casting tools

- In-house mold sampling with injection molding machines

- Metal Injection Molding (MIM)

- Punching, bending and compound tools

- Tools for medical technology

- Prototyping tools

- Particular surface treatments through coating, etching, laser engraving etc.